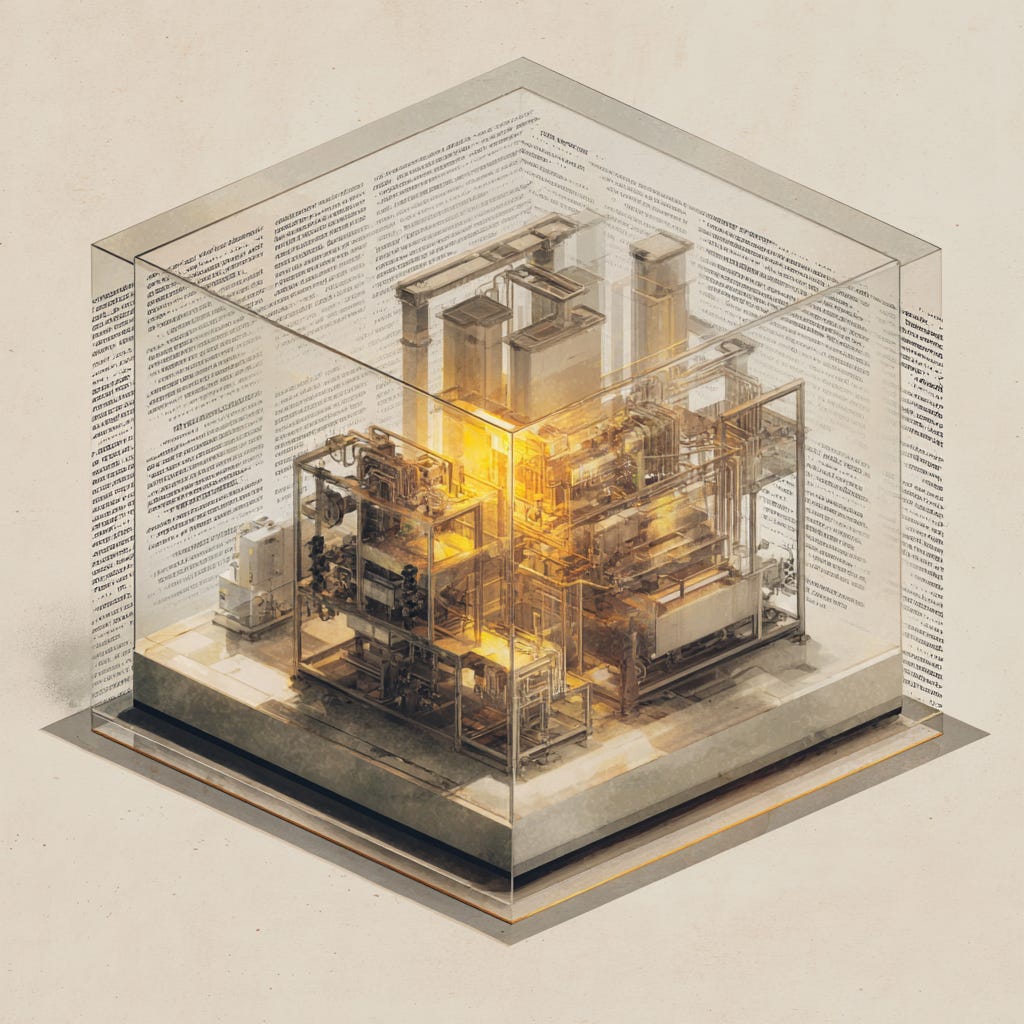

The Knowledge Embargo

Every problem has been solved somewhere. But solutions are trapped where they were found.

Welcome back to The Ledger - a weekly briefing of what’s happening inside complex systems around industrial decarbonisation. Welcome to Issue #18.

THE OPENING ENTRY

£3.2m saved annually in Teesside.

A 30% pressure drop eliminated in Bavaria.

A control sequence in Texas that prevents thermal fatigue failures.

None of them know about each other.

They work for the same company.

An engineering director at a global manufacturer shows me the numbers.

“We have 47 plants. I estimate 80% of our recurring problems have already been solved in at least one of them. But legal won’t let us share solutions between sites.”

The efficiency gain from simply copying what already works would exceed every R&D programme, every digital transformation, every net-zero initiative combined.

But the knowledge is embargoed.

Trapped by NDAs.

Buried in “proprietary processes.”

Locked behind liability walls.

We’re not short of innovation.

We’re drowning in it.

We just can’t share it.

FIELD REPORTS

1. The Sister Site Strangers

Two chemical plants. Same company. Same process. Forty miles apart.

Plant A solved a cooling instability problem in 2019. Saved £800k annually.

Plant B has the identical problem. Still losing £800k annually.

“We’re forbidden from sharing the fix,” Plant A’s engineer tells me. “Insurance says if it fails at their site, we’re liable. So we say nothing.”

Six years. £4.8 million wasted.

The solution sits in a drawer forty miles away.

The lawyer’s logic: sharing creates liability.

The planet’s logic: this is insanity.

2. The Acquisition Amnesia

A major industrial conglomerate. Twelve acquisitions over fifteen years. Each brought deep operational knowledge. All of it firewalled.

“The purchase agreements include knowledge barriers between divisions,” the integration director explains. “We own the companies, but we can’t access their methods across the group.”

Company A knows how to reduce steam demand by 40%.

Company B desperately needs that knowledge.

Same parent. Same balance sheet. Same climate targets.

Legal says no.

The efficiency gain from internal transfer: £45m.

The cost of insuring liability for sharing it: “Unquantifiable risk.”

Ownership without knowledge is a legal fiction.

Service without memory is a commercial one.

3. The Contractor’s Curse

A maintenance contractor services more than 200 industrial sites. He has seen every failure mode. He knows exactly what works.

“I fixed the same compressor issue at thirty plants last year,” he tells me. “Each one thinks it’s unique. Each pays for full diagnostics. I’m contractually forbidden from saying, ‘Plant X had this — here’s how we fixed it.’”

The NDA clauses are absolute:

No cross-pollination of solutions

No comparative performance data

No “lessons learned”

No informal knowledge transfer

“I could save UK industry half a billion pounds tomorrow just by talking,” he says. “But I’d lose every contract by lunchtime.”

Knowledge decays in captivity.

4. The Standard Silence

An industry working group. Fifteen companies. One shared problem.

“Everyone knows how to solve it,” the facilitator tells me afterwards. “But no one will share their method. It might give away competitive advantage.”

So they publish a “best practice” that reflects the lowest common denominator.

Everyone keeps using their better internal method.

The standard helps nobody.

Collective efficiency gain from sharing the best approach: ~20%.

Perceived competitive edge from hiding it: ~0.5%.

But 0.5% you own beats 20% you share.

5. The Researcher’s Wall

A university lab develops a heat exchanger design 60% more efficient than anything commercial.

“We published the paper,” the professor says. “But the implementation details - the stuff that makes it actually work - that’s embargoed by our industrial partners.”

The theory is public.

The knowledge to use it is private.

“We estimate fifty companies have independently solved the same implementation challenges,” she adds. “Each thinks they’re first.”

Total duplicated engineering hours: ~100,000.

Total efficiency lost to reinvention: incalculable.

THE EMBARGO ARCHITECTURE

Knowledge embargoes aren’t accidental. They’re layered.

Legal Barriers

NDAs

Liability clauses

IP protection - even internally

Insurance exclusions

Commercial Barriers

Defensive secrecy reflex

Supplier lock-in strategies

Contractor confidentiality

Customer exclusivity demands

Cultural Barriers

“Not invented here” syndrome

Knowledge as job security

Departmental protectionism

Expertise hoarding

Each rational in isolation.

Together, industrially insane.

THE MULTIPLICATION OF IGNORANCE

UK industrial sites: ~6,000

Common efficiency problems: ~200

Sites experiencing each problem: ~2,000

Sites that have solved each problem: ~100

Meaning: 1,900 sites struggle with problems already solved 100 times over.

Estimated efficiency trapped in embargoed knowledge: 15–20%.

Not future potential.

Not hypothetical innovation.

Existing solutions. Proven. Operational.

Just legally radioactive.

The Knowledge Re-Solve Ratio

For every industrial efficiency solution implemented once, it is independently rediscovered 10–20 times elsewhere.

The transition isn’t failing for lack of ideas.

It’s paying repeatedly for the same ones.

THE CONSULTANCY PARADOX

Who thrives under the embargo? Consultants.

“My business model is selling Company B the solution Company A already developed,” a boutique consultancy founder admits. “I’m basically a knowledge launderer.”

The loop:

Company A develops solution under NDA

Consultant observes it

Consultant “independently” recreates it

Company B buys it as innovation

Consultant profits

“The embargo created a £2bn consulting market that just repackages trapped intelligence.”

Consultants didn’t create the embargo.

They simply monetised the silence it produced.

THE INSURANCE IMPOSSIBILITY

The ultimate justification is liability.

“If we share a solution and it fails elsewhere, we’re exposed,” legal teams insist.

The actuarial reality:

Liability claims from shared operational knowledge: ~0

Efficiency loss from not sharing: ~20%

Insurance cost to cover sharing: ~0.1% of savings

“The risk is theoretical,” an insurance executive admits. “The waste is actual. But theoretical risk has better lawyers.”

THE DIGITAL DELUSION

“Industry 4.0 will solve this,” vendors promise.

Reality:

Every optimisation is proprietary

Every algorithm is protected

Every improvement is paywalled

“We digitised the embargo,” a CDO tells me. “Now the knowledge is trapped in software licences instead of filing cabinets.”

The accounting evolves.

The chemistry doesn’t.

THE OPERATOR’S PLAYBOOK

For engineers

Document principles, not site-specific fixes

Build informal peer networks below legal radar

Use academia as a translation layer

Recreate known solutions in “clean rooms”

For management

Calculate the real cost of your embargo

Force legal to price actual vs theoretical risk

Create internal knowledge amnesty programmes

Accept that proprietary advantage is usually imaginary

For policymakers

Exclude efficiency knowledge from IP protection

Create safe harbours for solution sharing

Mandate pooling for safety-critical systems

Recognise climate risk supersedes secrecy

THE LEDGER LINE

Every industrial plant is surrounded by invisible walls.

Not physical.

Not digital.

Legal.

Inside them, engineers solve problems - real ones. Proven ones. Valuable ones.

The solutions can’t leave. The problems multiply endlessly.

We didn’t fail to build a learning system. We built a system optimised to forget safely.

The greatest barrier to industrial transformation isn’t technology. It isn’t capital. It isn’t even ambition.

It’s the paragraph in the contract marked “proprietary and confidential.”

The energy transition doesn’t need more innovation.

It needs fewer lawyers.

The solutions already exist - thousands of them. Tested. Operational. Sitting in filing cabinets.

Protected by NDAs. Embargoed by paranoia.

The knowledge exists.

The solutions work.

The failure is contractual.

Thanks for reading, and please share The Ledger if you have found it useful or insightful in any way.

Here’s to what’s possible

Dom