The Reliability Tax

Why the most dependable systems waste the most energy

Welcome back to The Ledger - a weekly briefing of what’s happening inside complex systems around industrial decarbonisation. Let’s get straight into Issue #10.

THE OPENING ENTRY

The chemical plant’s boiler has run for 23 years without unplanned downtime. Perfect reliability. Engineering pride.

Eighteen percent of the fuel wasted - and nobody will touch it.

Not just here. Every plant has one: a system that’s perfect on uptime and bleeding money in fuel. Walk into any industrial facility and you’ll find the same pattern: the most reliable systems are systematically the least efficient. This isn’t bad engineering - it’s deliberate. We’ve designed thermal systems to never fail, and paid for that guarantee in fuel.

That trade-off made sense at £15/MWh. At £150, it doesn’t - but the systems are still designed for the old world.

FIELD REPORTS

1. The Oversizing Tax

Food processing plant, East Midlands. Three boilers, each rated at 12 MW. Peak winter demand hits 28 MW for maybe 40 hours a year. The rest of the year, two boilers loiter at 35-40% load.

The operations manager knows this. “We sized for the coldest day in 2010. Haven’t seen those conditions since.”

Boiler efficiency at 40% load: 68%

At design load: 88%

That 20-point gap costs £340,000 annually. The plant will hit peak demand four times this winter, for perhaps 30 hours total. That’s £11,000 per hour of potential risk.

They’re paying a £340k insurance premium for 30 hours of capacity they might need - and because the boilers never fail, nobody questions it.

2. The Redundancy Cost

Manufacturing facility, three boilers: two running, one standby. The standby sits there pressurised and hot, waiting for failure that hasn’t come in eight years.

“If we lose a boiler, we lose production. Insurance.”

But the standby isn’t free. Pressurised at 10 bar, insulated but radiant, it loses 180 kW. That’s 1.58 million kWh per year.

Annual cost: £110,000

Eight-year cost: £880,000

CO₂ equivalent: 290 tonnes annually

They haven’t needed it once.

It’s invisible in the accounts. It never shows as a line item.

When I suggested cycling the standby through scheduled operation to recover some losses, the site engineer looked at me like I’d suggested juggling chainsaws.

3. The Setpoint Inflation

Textile dye house. Process requires steam at 8 bar. Control system setpoint: 10 bar.

“Why 10?”

“Safety margin.”

“How much margin do you need?”

“Always run it this way.”

Every bar of pressure above requirement costs 2-3% more fuel. Two bars of unnecessary pressure: 6% waste, or £95,000 annually for this facility.

I traced the setpoint history. Original spec: 8 bar. In 1997, an operator bumped it to 8.5 after a quality issue. New supervisor in 2003 saw 8.5, rounded to 9 “for safety.” Control system upgrade in 2011, engineer set it to 10 “to match the old system, plus margin.”

The setpoint drifted 25% higher over 15 years. No single decision wrong, all of them additive.

4. The Overnight Waste

Chemical plant, continuous process. Daytime production: 100% thermal load. Night shift: 20% production, 80% of the heating capacity.

“Why keep base load at 80% overnight?”

“Startups are risky. Thermal stress on equipment, process stability, what if night shift has an issue?”

Night shift gas burn they don’t use: 12,000 kWh/night

Annual cost: £480,000

“We tried load-following fifteen years ago. Had a cold start issue, took six hours to recover. Never doing that again.”

That six-hour incident fifteen years ago is costing them half a million pounds a year.

5. The Ancient Control Lock-In

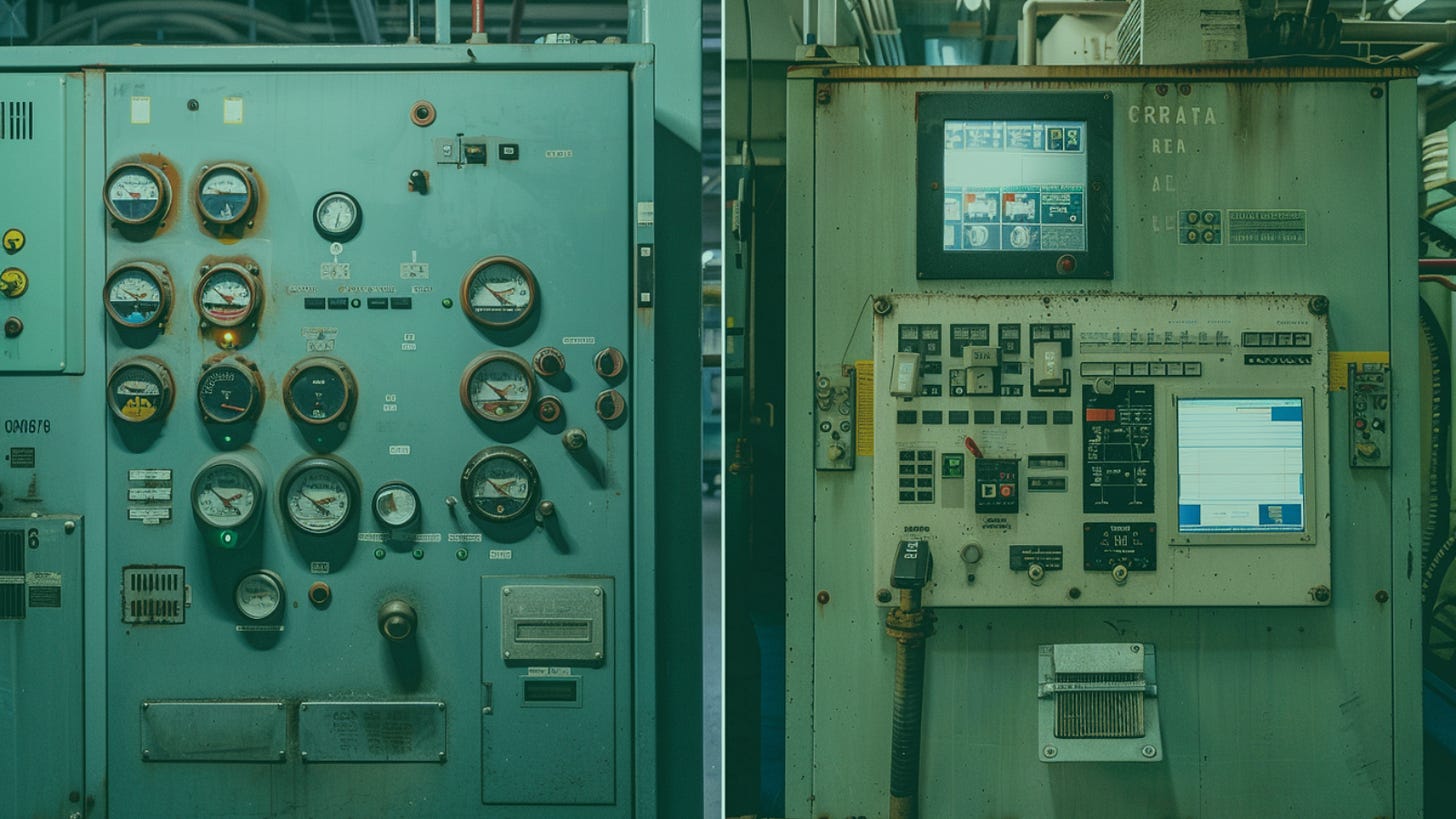

Textile operation, 1980s pneumatic control system. The control cabinets hum in a corner, beige and immaculate. Works perfectly. Never fails. Operators trust it like a heartbeat.

“Why not upgrade to modern controls?”

“This system has run for 40 years without failing. Why would we replace it?”

Because the 1980s system can’t modulate load, forecast demand, or respond to real-time pricing. It can’t track efficiency metrics across operating modes or adjust setpoints dynamically based on actual demand.

The plant manager is proud of the system’s reliability. But that reliability is costing 15-20% efficiency they can’t access without modern controls.

That’s roughly £275,000 a year, locked inside a control system they won’t touch because it never fails.

WHAT THE LEDGER REVEALS

Industrial thermal systems are designed for reliability first, efficiency second. This hierarchy made sense in a different world:

Old world: Cheap energy / Expensive downtime

New world: Expensive energy / Cheap intelligence

The cost structure has inverted. Energy is roughly eight times the historical baseline. Efficiency gains that were marginal (65% to 72%) are now substantial (65% to 92%+). Modern controls enable both reliability and efficiency simultaneously.

We’re operating systems designed for a different economic reality. The oversizing, the redundancy, the conservative setpoints, the base-load operations, the ancient controls - none of these are mistakes. They’re features. They deliver reliability.

The question isn’t whether reliability matters. It’s whether we’re still optimising the right trade-off.

Because here’s what’s changed: modern control systems and operational methods can deliver both. Variable-speed drives, predictive controls, smart load-following, real-time optimisation - these aren’t experimental. They’re proven. The technology exists to maintain uptime while recovering the 15–25% efficiency locked in “reliable operation.”

The 23-year boiler that’s never failed? It will keep running. The question is whether you’ll keep paying £200,000 a year for the privilege of never touching it.

OPERATOR’S PLAYBOOK

Five questions to surface the reliability tax in your facility:

1. Oversizing tax - are you paying for capacity you’ll never use?

If your boilers run below 60% load most of the time, calculate the efficiency penalty and multiply by operating hours. Compare annual cost to actual peak demand frequency.

2. Redundancy cost - what’s your standby system burning?

That backup boiler sitting pressurised isn’t free. Measure radiant losses, calculate annual energy cost, compare to your actual downtime risk over the past decade.

3. Setpoint inflation - where have your margins grown beyond requirements?

Find your steam pressure, hot water temperature, air temperature setpoints. Compare to actual process minimums. Every degree or bar above requirement has a fuel cost.

4. Overnight baseline - what’s running when production isn’t?

If you’re running 70-80% capacity when production is at 20%, you’re paying the continuous operation tax. Modern controls can load-follow safely - if you’re willing to design the transition.

5. Control system lock-in - what could better controls enable?

Your 1980s control system is reliable. It’s also leaving 15-20% efficiency on the table. The question isn’t whether to keep it running - it’s whether you can afford not to upgrade.

Every one of these questions is uncomfortable. That’s how you know they matter.

THE LEDGER ENTRY

Reliability and efficiency aren’t enemies. But we’ve designed them that way.

FIELD NOTES

Why this matters now

UK industrial gas prices averaged £24/MWh in 2020 and peaked at £180/MWh in winter 2022. Even at today’s £95/MWh, that’s a fourfold structural increase.

Every percentage point of efficiency that was “nice to have” in 2019 is now material to P&L.

The Carbon Border Adjustment Mechanism (CBAM) starts enforcement in 2026. Process emissions matter, but so does fuel consumption. A 15% efficiency gain in a cement kiln or steel reheat furnace cuts both cost and carbon intensity. The plants that move first gain a structural advantage. The ones that wait will pay twice - in fuel and in carbon tariffs.

The psychology of touching working systems

Three operators told me variations of the same line:

“If I change something and it breaks, that’s my fault. If it keeps running the way it always has and costs too much, that’s not my problem.”

That’s not laziness. It’s rational risk management in a culture that punishes failure more than it rewards efficiency.

The plant manager who updates controls and has one bad startup loses credibility for months.

The one who leaves the system untouched and burns 18% more fuel just runs a high-cost facility - which is everyone’s problem, and therefore no one’s problem.

The reliability tax persists because the cost is diffuse and the risk of change is personal.

What’s actually proven

I still hear “modern controls are unproven” from operators running systems designed in 1983.

Here’s what’s actually deployed - and working - at scale:

Predictive load-following — Neste Rotterdam refinery

Variable thermal load based on production schedules since 2019.

Uptime: 99.7% Efficiency gain: 12%

AI-optimised combustion — BASF Ludwigshafen steam network

Real-time optimisation since 2021.

Unplanned outages: 0 Fuel reduction: 8–11%

Smart redundancy cycling — Tata Steel Port Talbot

Rotating standby boilers through scheduled operation since 2020.

Savings: £2.1 M recovered over three years Reliability impact: none

These aren’t pilots. They’re production systems in plants where downtime costs millions per hour.

The technology works. What’s missing is permission to deploy it.

What I’m tracking

Plants that move on this in 2025–26 will enjoy five to eight years of lower operating costs before the laggards catch up.

By 2030, efficient operation won’t be a competitive edge - it’ll be table stakes.

The question is whether your facility leads the transition or gets dragged through it by carbon pricing and energy costs.

If you’re seeing the reliability tax in your operations - or already tackling it - I want to hear what you’re finding.

Thanks for reading, and please share The Ledger if you have found it useful or insightful in any way.

Here’s to what’s possible

Dom

The Ledger tracks patterns hiding in plain sight. Send me what you’re seeing - the old systems everyone trusts, the night loads that never drop, the controls nobody touches. That’s where the next Ledger starts.